European and Japanese researchers optimise renewable methanol production

“Renewable methanol (green) has an impressive potential to help decarbonising the transport sector. It can cut CO2 emissions by up to 95%, reduce NOx emissions by up to 80%, and completely eliminate SOx and particulate matter emissions. It is a promising technology that can play an important role in making Europe the first climate-neutral continent” explained Adolfo Benedito Borrás, LAURELIN Technical Coordinator and Head of the Materials Research Department at AIMPLAS.

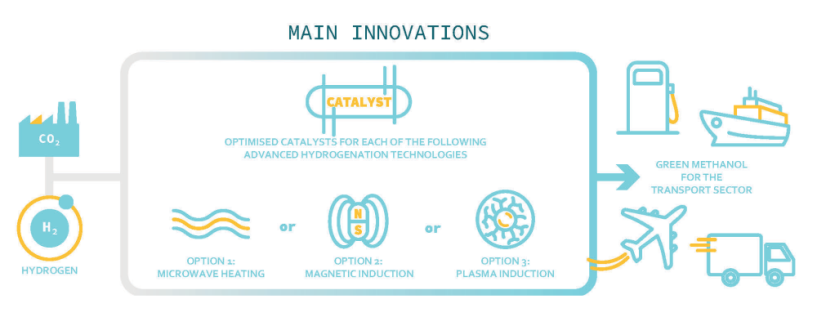

But hydrogenation of CO2 into renewable methanol (green) has strong limitations related to the process, the energy consumption and production costs. CO2 is generally unreactive, and hydrogenation is impossible without the use of a catalyst, a substance added to accelerate the chemical reaction of H2 with CO2. LAURELIN’s team therefore is developing new catalyst systems perfectly adapted to advanced reactor technologies to reduce energy consumption of the methanol synthesis from CO2, and therefore its cost.

The team is working on three promising (reactor) technologies: microwave, non-thermal plasma induction and magnetic induction. They are finalising the construction of the three corresponding reactors for CO2 conversion to renewable methanol (green).

Involving universities, research organisations and SMEs from Belgium, Germany, Japan, Netherlands, Spain and the United Kingdom, LAURELIN is a 48-month project funded by the European Union’s Horizon 2020 programme and the Japan Science and Technology Agency (JST). Learn more about the LAURELIN project by watching the project video.

The LAURELIN project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement n. 101022507. It reflects only the author’s view. The Agency is not responsible for any use that may be made of the information it contains.

This research is supported by the Japan Science and Technology Agency (JST) under the SICORP programme (grant no. JPMJSC2101).